RIGHT TIME TO EXPAND FOR NEW AND QUALIFIED CNC VENDORS

As a business owner or purchasing manager, it’s important to have a reliable list of qualified CNC vendors that you can turn to for your manufacturing needs. However, there may come a time when you need to expand this list in order to meet the demands of your business.

Signs for new and qualified CNC vendors

Here are a few signs that it may be time to expand your list of qualified CNC vendors:

- You are experiencing delays in the production process due to a lack of available capacity from your current vendors. If you are consistently having to wait for CNC work to be completed, it may be time to bring on additional vendors to help meet demand.

- Your current vendors are unable to handle the complexity of your projects. If you are producing high-precision parts that require advanced CNC machining capabilities, it may be necessary to find vendors with the expertise and equipment to handle these types of projects.

- You are looking to diversify your supply chain. It’s always a good idea to have a diverse group of suppliers in order to reduce the risk of disruption in the event that one of your vendors experiences a problem. Expanding your list of qualified CNC vendors can help you diversify your supply chain and increase the resilience of your business.

- You are looking to reduce costs. It’s not uncommon for businesses to periodically review their vendor list in order to identify opportunities to reduce costs. Expanding your list of qualified CNC vendors can give you more options and allow you to negotiate better pricing.

- You are entering a new market. If you are expanding your business into a new market, it may be necessary to bring on additional CNC vendors in order to meet the demand for your products.

Steps to expand your qualified CNC vendors

So, how do you go about expanding your list of qualified CNC vendors? There are a few steps you can take:

- Identify your needs. Determine what you are looking for in a CNC vendor and make a list of the specific capabilities and qualifications you require.

- Research potential vendors. Look for vendors that meet your criteria and have a good reputation in the industry. You may want to consider reaching out to industry associations or consulting with industry experts to get recommendations.

- Evaluate potential vendors. Once you have a list of potential vendors, it’s important to carefully evaluate them in order to determine which ones are the best fit for your business. This may involve visiting their facilities, reviewing their capabilities and capacity, and speaking with their customers to get a sense of their quality and reliability.

- Negotiate terms and conditions. Once you have identified a few qualified CNC vendors that you would like to work with, it’s important to negotiate terms and conditions that are mutually beneficial for both parties. This may include pricing, delivery schedules, payment terms, and any other relevant details.

Important Characteristics of CNC Vendors

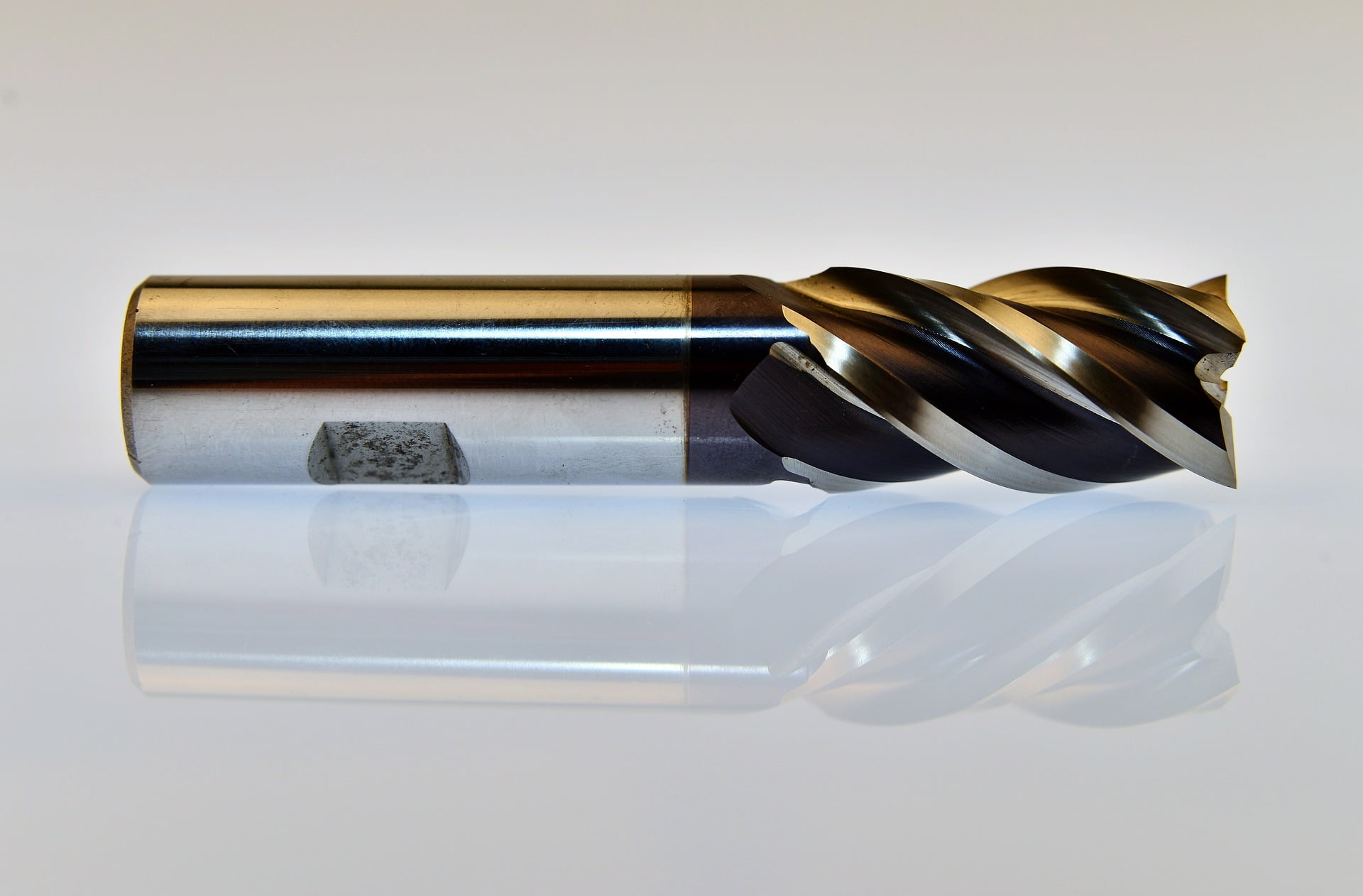

CNC vendors play a crucial role in the manufacturing industry as they provide the necessary tools and technology for businesses to produce high-quality products efficiently.

Here are some characteristics of CNC vendors:

- Expertise in CNC technology: A good CNC vendor will have a deep understanding of CNC technology and how it can be applied in different manufacturing processes. They should be able to provide guidance and support to customers on the best CNC solution for their needs.

- Wide range of products: A reputable CNC vendor will offer a wide range of CNC products, including CNC machines, tooling, and software. This allows customers to find a complete CNC solution that meets their specific requirements.

- Quality products: Quality is a key characteristic of any CNC vendor. Customers should be able to trust that the CNC services they purchase will be reliable and durable. A good CNC vendor will have strict quality control measures in place to ensure that their products meet the highest standards.

- Strong customer support: CNC services can be complex and may require ongoing support and maintenance. A good CNC vendor will have a team of experts available to assist customers with any issues that may arise. This includes providing technical support, training, and maintenance services.

- Innovative solutions: The manufacturing industry is constantly evolving, and CNC vendors should be at the forefront of innovation. A good CNC vendor will be constantly researching and developing new products and technologies to help their customers stay ahead of the competition.

Expanding your list of qualified CNC vendors can be a valuable step for businesses looking to increase production capacity, improve the complexity of their products, diversify their supply chain, reduce costs, or enter new markets. By following these steps, you can find reliable CNC vendors that can help your business succeed.